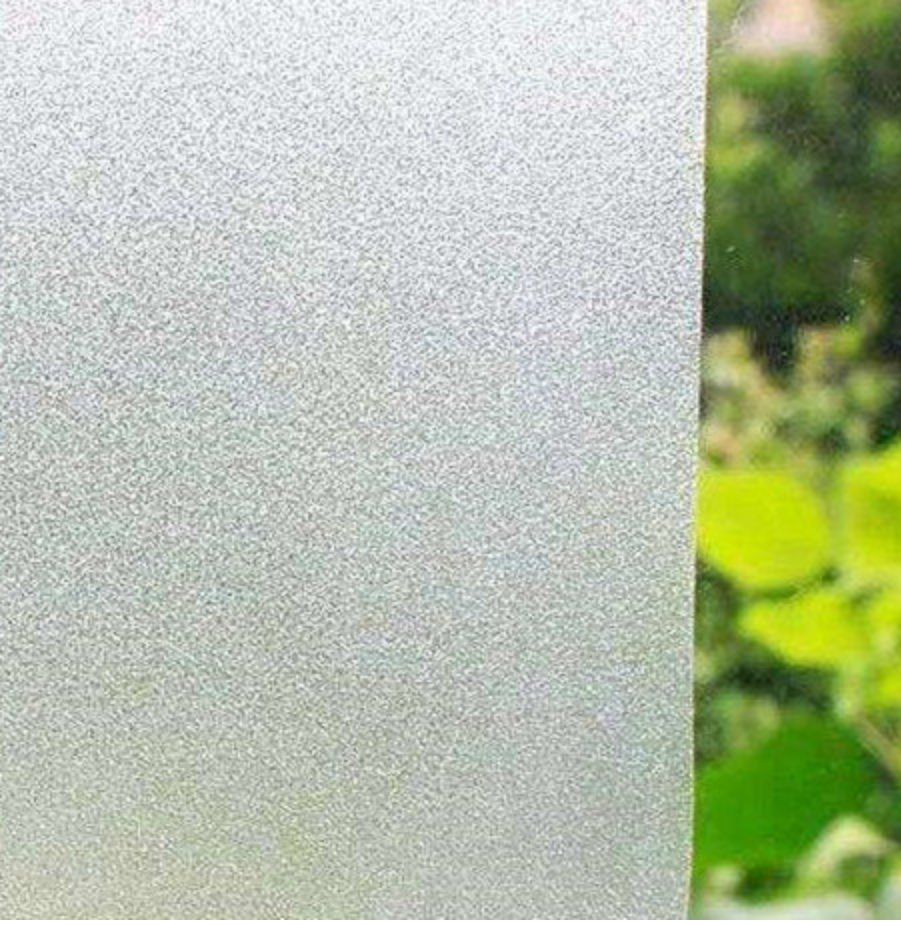

Frosted glass production process

Cleaning and drying: First, clean the flat glass thoroughly to remove dust and stains, and then dry it to ensure that the glass surface is clean and flawless.

Hoisting: Load the cleaned and dried flat glass onto the hoisting frame, use a toothed rubber bracket to protect the glass, and keep the glass vertically discharged to ensure that there is an appropriate distance between the glass.

Corrosion: Immerse the glass together with the hoisting frame in the corrosion box, and use the corrosion liquid to corrode the glass surface to form a rough surface texture. The corrosion time is usually 5-10 minutes.

Softening: Residues will be attached to the surface of the corroded glass, and it needs to be softened in a softening box to remove the residues.

Cleaning: Frosted glass will carry chemicals during the corrosion and softening process, so it needs to be thoroughly cleaned.

Drying: The cleaned frosted glass is placed in a drying room for drying to complete the production of frosted glass.

Application of frosted glass

Home decoration: Frosted glass is often used for partitions, screens, doors and windows in homes to enhance the privacy and aesthetics of the space.

Office decoration: In office environments, frosted glass can be used to make partitions and meeting room doors and windows to create a comfortable and private working environment.

Photography and lighting: The diffuse reflection characteristics of frosted glass make it very popular in photography and lighting design, providing a soft light effect.

Chemical reagent bottles: Frosted glass is also used for the mouth of chemical reagent bottles to ensure sealing and prevent reagent volatilization.

Frosted glass has been widely used in many fields due to its unique visual effects and practicality. With the advancement of technology and the growth of market demand, the production process of frosted glass is also being optimized to meet higher quality and performance requirements. At the same time, environmental protection and personalized customization have also become important trends in the development of the frosted glass industry.

- 上一篇:Painted glass

- 下一篇:Screen printing glass